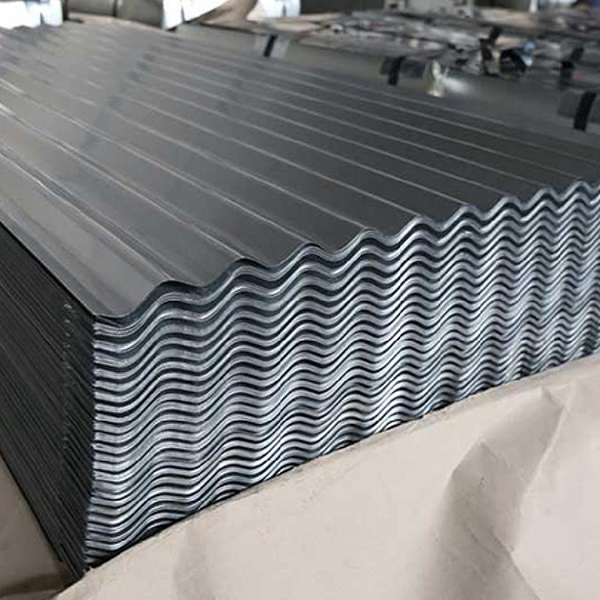

Stainless steel cold rolled coil Factory – Galvanized corrugated roofing sheet SGCC/CGCC corrugated roofing sheet hot sale color coated plate – Future Metal

Stainless steel cold rolled coil Factory – Galvanized corrugated roofing sheet SGCC/CGCC corrugated roofing sheet hot sale color coated plate – Future Metal Detail:

Features

⒈ Light weight: 10-14 kg/m2, equivalent to 1/30 of a brick wall.

⒉ Thermal conductivity: λ<=0.041w/mk.

⒊High strength: It can be used as a load-bearing board for ceiling enclosure structure, resisting bending and compression; beams and columns are not used in general houses.

⒋Bright color: no surface decoration is required, and the anti-corrosion layer of the color galvanized steel plate can be maintained for 10-15 years.

⒌The installation is flexible and fast: the construction period can be shortened by more than 40%.

Install

Dosage calculation formula

1. Two-sided sloping roof

Description of two-sided sloping roof

⒈The area of the roof: length×width.

⒉The total length of the required tile: roof area ÷ 0.855 (the effective width of the tile is 0.855M/piece).

⒊The number of tiles: (roof length÷0.855m)×2.

⒋The number of ridge tiles: roof length ÷ 2.4m (the effective length of ridge tiles is 2.4M/root).

⒌Number of sealing strips: (length ÷ 0.7m) × 2 (sealing strip 0.7M/piece).

⒍The quantity of the eaves cover: (length ÷ 0.7m) × 2 (the eaves cover 0.7M/piece).

⒎The number of special nails: 4PCS/㎡.

⒏The roof angle is less than or equal to 120 degrees.

2. Four-sided sloping roof

Description of sloping roof

⒈Budget roof area: (A+B+C+D)×117% (inclination and loss).

⒉The total length of the required tile: roof area ÷ 0.855 (the effective width of the tile is 0.855M/piece).

⒊The number of ridge tiles: (a×2+b+c×2) ÷ 0.7 (the effective length of ridge tiles is 2.4M/piece).

⒋Number of sealing strips: (length + width) ÷ 0.7 (sealing strip 0.7M/piece).

⒌The number of the eaves cover: (length + width) × 2÷0.7 (the eaves cover 0.7M/piece).

⒍The number of special nails: 4PCS/㎡.

Pre-installation engineering

Four-sided slope

1: The blue dashed line and the red dashed line are the horizontal and vertical skeletons respectively.

2: a The best distance is 50CM.

3: The distance of b is preferably 50-70CM.

Two sides slope

⒈Choose the material of the frame, both wood structure and steel structure are suitable.

⒉The construction surface needs to be tidied and leveled.

⒊Frame material specifications: Wood specifications are 45MM×45MM or more, steel specifications are 40MM×40MM or more.

⒋ The longitudinal spacing of the frame should be kept between 50CM~70CM, and the horizontal spacing must be a multiple of 25CM, preferably not greater than 50M. Use screws as close as possible and weld firmly.

Installation work

The correct way of laying tiles

⒈Overlapping type (applicable to roofs with length≦15M)

⒉Staggered type (applicable to roofs with length ≧15M)

Correct use of special nails

⒈The special nail must be hit in the middle of the tile bone to have a waterproof effect.

⒉The fixed interval of special nails is 50cm~100cm (preferably 4 pieces/㎡).

⒊The special nails must be driven from the lower end of the tile toward the roof to have a beautiful, sealed and neat effect.

Install the sealing strip ridge tile cover

⒈ Separate the sealing strip in half, and place ridge tiles on the roof according to the tile type and fix them with special nails.

⒉The joints of the side tiles are sealed with cement and then directly covered with ridge tiles, and the bottom of the ridge tiles is finished with a small tile stop.

⒊The lower end of the tile, namely the eaves, is directly installed with the eaves cover and fixed with screws.

4. At the ridge tile junction, the contrast interface is trimmed with scissors and overlapped and sealed with glass glue.

Waterproof treatment of the protruding part

First, make a V-shaped material. Different materials and specifications can be selected, depending on the actual situation. After installing the water connection at the bottom, lay the color steel tiles on the top.

Connection installation on inclined surface

Refers to the construction where the two roof tiles are cut according to the angle and length, and the bottom is installed with water receiving treatment. First, install the water receiving material (ie gutter) under the tiles, and then use waterproof adhesive or cement for finishing.

Precautions

1. Wear the necessary safety equipment (such as gloves, helmets, safety belts and other tools).

2. The installation worker needs to be a professional with a certificate.

3. The skeleton must be firm when installed.

4. When installing and walking on the tiles, try to step on the middle part of the tiles to avoid stepping on the edges of the tiles.

5. Be careful to install in bad weather.

Product Display

Product detail pictures:

Related Product Guide:

Bear "Customer 1st, Good quality first" in mind, we work closely with our prospects and supply them with efficient and professional services for Stainless steel cold rolled coil Factory – Galvanized corrugated roofing sheet SGCC/CGCC corrugated roofing sheet hot sale color coated plate – Future Metal , The product will supply to all over the world, such as: Rotterdam, British, Tanzania, Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.