Famous Polished aluminum cylinder Factories – Cylinder Tube DNC Pneumatic Cylinder Aluminum Tube – Future Metal

Famous Polished aluminum cylinder Factories – Cylinder Tube DNC Pneumatic Cylinder Aluminum Tube – Future Metal Detail:

The main purpose of hydraulic cylinder

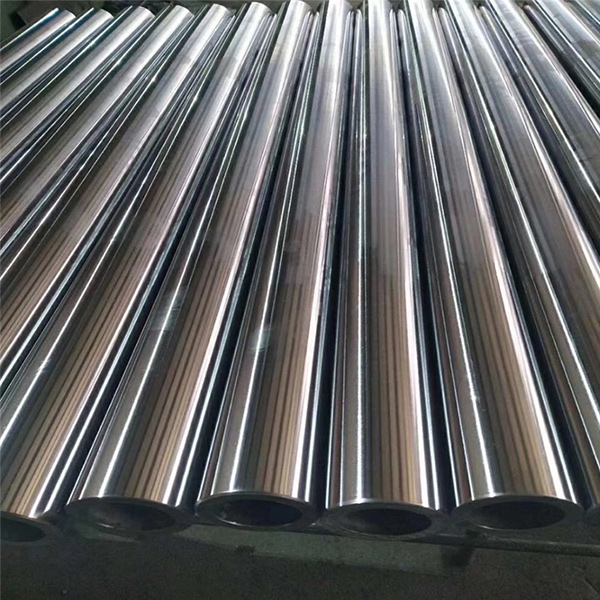

Hydraulic and pneumatic cylinders; hydraulic pipelines; pipes for spinning, textile and printing machinery;

Automobile shock absorber pipe; shaft sleeve; piston rod and precision alloy steel pipe.

According to customer requirements, we can also provide: fixed-length tubes, honing tubes, and special heat-treated tubes.

In order to obtain a good honing effect, in addition to the selection of good honing tools and the correct selection of grinding rod materials and particle size, the use of process parameters during honing also has a large impact on processing quality and productivity. Hydraulic cylinder refers to the pressure exerted by the sand bar on the surface of the workpiece, which is determined by the hardness of the processed surface, the nature of the grinding bar and the requirements of the processed surface roughness.

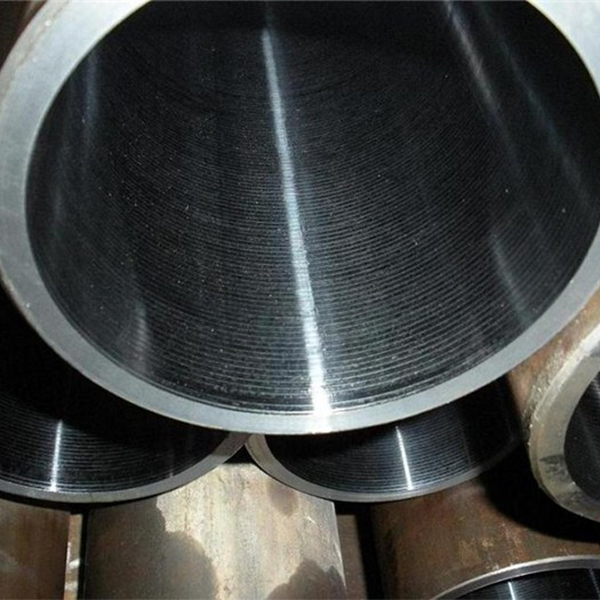

Cylinders are the main components of hydraulic cylinders, single pillars for mines, hydraulic supports, gun barrels and other products. The quality of their processing directly affects the life and reliability of the entire product. The cylinder barrel has high processing requirements, and its inner surface roughness is required to be Ra0.4~0.8&um, and the requirements for coaxiality and wear resistance are strict.

The use of rolling processing, because the surface layer leaves the surface residual compressive stress, it helps to close the surface micro-cracks and hinder the expansion of erosion. So as to improve the surface corrosion resistance, and can delay the generation or expansion of fatigue cracks, thereby improving the fatigue strength of the cylinder. Through roll forming, a cold work hardened layer is formed on the rolled surface, which reduces the elastic and plastic deformation of the contact surface of the grinding pair, thereby improving the wear resistance of the inner wall of the cylinder and avoiding burns caused by grinding. After rolling, the surface roughness value is reduced, which can improve the matching performance.

Product Display

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict quality control, reasonable price, superior service and close co-operation with customers, we are devoted to providing the best value for our customers for Famous Polished aluminum cylinder Factories – Cylinder Tube DNC Pneumatic Cylinder Aluminum Tube – Future Metal , The product will supply to all over the world, such as: Ecuador, Luxemburg, Florence, We'd like to invite customers from abroad to discuss business with us. We can present our clients with high quality products and excellent service. We're sure that we'll have good cooperative relationships and make a brilliant future for both parties.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!