Stainless steel pipe welding Factory – carbon steel rectangular tube – Future Metal

Stainless steel pipe welding Factory – carbon steel rectangular tube – Future Metal Detail:

According to the production process, square and rectangular pipes are divided into: hot-rolled seamless square pipes, cold rolled seamless square pipes, extruded seamless square pipes, and welded square pipes.

Among them, the welded square tube is divided into

1. According to the process – arc welded square tube, resistance welded square tube (high frequency, low frequency), gas welded square tube, furnace welded square tube

2. According to the welding seam – straight seam welded square tube, spiral welded square tube.

Material classification

The square tube is divided into: ordinary carbon steel square tube, low alloy square tube.

1. Common carbon steel is divided into: Q195, Q215, Q235, SS400, 20# steel, 45# steel, etc.

2. Low alloy steel is divided into: Q345, 16Mn, Q390, ST52-3, etc.

Production Standard Classification

According to the production standard, the square pipe is divided into: national standard square pipe, jis square pipe, BS square pipe, ASTM, AISI square pipe, EN square pipe, DIN square pipe.

Sizes

|

Product Name |

Square/Rectangular Pipe |

|

Material |

S235JR, S355JR, S275JR, C350LO, C250LO, G250, G350(C450LO) |

|

Material Chemical Composition |

Tensile strength: 315-430(Mpa) Yield steength:195(Mpa)Elongation 33 C 0.06-0.12 Mn 0.25-0.50 Si≤0.30 S≤0.050 P≤0.045 |

|

Shape |

Square / Rectangular |

|

Outer Dia(mm) |

15*15mm-1200*1200mm / 10*20mm-700*300mm |

|

Wall Thickness(mm) |

0.6-80mm |

|

Length |

3-12.5M |

|

Surface Treatment |

1 、 Black,Pre-galvanized2、Oiled,powder coating3、Galvanized as your requirement

PS: Pre galvanized steel pipe: 60-150g/m2;Hot dipped galvanized steel pipe: 200-400g/m2 |

|

End Finish |

Plain/ beveled ends or threaded with sockets/coupling and plastic caps. |

|

Package |

Packing in bundle with steel strips; with seaworthypackage at the end; could be done with your requirement. |

|

Inspection |

With Chemical Composition and Mechanical Properties Testing; HydrostaticTest, Dimensional and Visual Inspection, With Nondestructive Inspection |

|

Application |

Construction pipe, machine structure pipe, agriculture equipment pipe, water and gas pipe,Greenhouse pipe, Building material, Furniture tube, Low pressure fluid tube, etc |

|

HS Code |

7306309000 |

|

Advantages |

1: Special design available according to requirement

2: Pipe can be necked dowm, punching hole on pipe wall. 3: Pipe fittings, elbows are available. 4: All production process are under the ISO9001:2000 strictly |

| Package Details | Standard seaworthy package(wooden boxes package,pvc package, or other package) |

| Container size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) |

| 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) | |

| 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) |

Uses

Square pipes for decoration, square pipes for machine tools, square pipes for machinery industry, square pipes for chemical industry, square pipes for steel structures, square pipes for shipbuilding, square pipes for automobiles, square pipes for steel beams and columns, square pipes for special purposes.

Standard of carbon steel rectangular pipe

| ASTM A53 Gr.B | Black and hot-dipped zinc-coated steel pipes welded and seamless |

| ASTM A106 Gr.B | Seamless carbon steel for high temperature service |

| ASTM SA179 | Seamless cold-drawn low-carbon steel heat exchanger and condenser tubes |

| ASTM SA192 | Seamless carbon steel boiler tubes for high pressure |

| ASTM SA210 | Seamless Medium-carbon boiler and superheater tubes |

| ASTM A213 | Seamless alloy-steel boiler, superheater, and heat-exchanger tubes |

| ASTM A333 GR.6 | seamless and welded carbon and alloy steel pipe intended for use at low temperatures. |

| ASTM A335 P9,P11,T22,T91 | Seamless ferritic alloy-steel pipe for high-temperature service |

| ASTM A336 | Alloy steel forgings for pressure and high-temperature parts |

| ASTM SA519 4140/4130 | Seamless carbon for mechanical tubing |

| API Spec 5CT J55/K55/N80/L80/P110/K55 | Seamless steel pipe for casing |

| API Spec 5L PSL1/PSL2 Gr.b, X42/46/52/56/65/70 | Seamless steel pipe for line pipe |

| DIN 17175 | Seamless steel tube for elevated temperture |

| DN2391 | Cold drawn seamless prevision pipe |

| DIN 1629 | Seamless circular unalloyed steel tubes subject to special requirements |

Chemical components & mechanical properties

|

Standard |

Grade |

Chemical Components (%) |

Mechanical Properties |

|||||

| ASTM A53 | C | Si | Mn | P | S | Tensile STrength(Mpa) | Yield STrength(Mpa) | |

| A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.06 | ≥330 | ≥205 | |

| B | ≤0.30 | - | ≤1.2 | ≤0.05 | ≤0.06 | ≥415 | ≥240 | |

| ASTM A106 | A | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥415 | ≥240 |

| B | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥485 | ≥275 | |

| ASTM SA179 | A179 | 0.06-0.18 | - | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 |

| ASTM SA192 | A192 | 0.06-0.18 | ≤0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 |

| API 5L PSL1 | A | 0.22 | - | 0.90 | 0.030 | 0.030 | ≥331 | ≥207 |

| B | 0.28 | - | 1.20 | 0.030 | 0.030 | ≥414 | ≥241 | |

| X42 | 0.28 | - | 1.30 | 0.030 | 0.030 | ≥414 | ≥290 | |

| X46 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥434 | ≥317 | |

| X52 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥455 | ≥359 | |

| X56 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥490 | ≥386 | |

| X60 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥517 | ≥448 | |

| X65 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥531 | ≥448 | |

| X70 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥565 | ≥483 | |

| API 5L PSL2 | B | 0.24 | - | 1.20 | 0.025 | 0.015 | ≥414 | ≥241 |

| X42 | 0.24 | - | 1.30 | 0.025 | 0.015 | ≥414 | ≥290 | |

| X46 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥434 | ≥317 | |

| X52 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥455 | ≥359 | |

| X56 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥490 | ≥386 | |

| X60 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥517 | ≥414 | |

| X65 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥531 | ≥448 | |

| X70 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥565 | ≥483 | |

| X80 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥621 | ≥552 | |

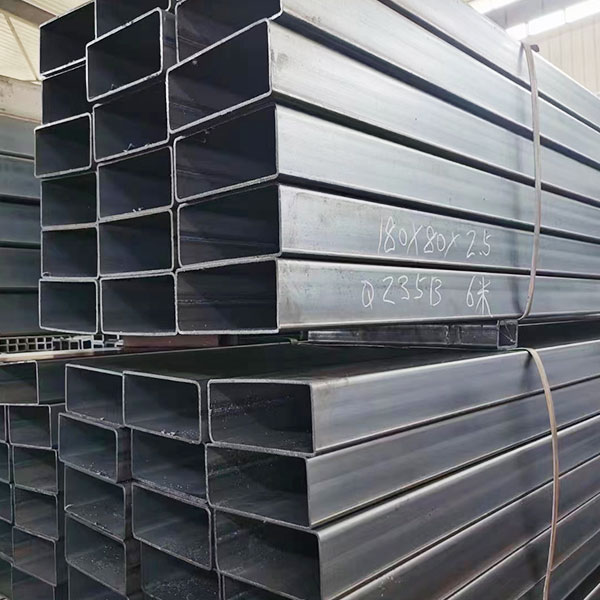

Product Display

Product detail pictures:

Related Product Guide:

It is our responsibility to meet your needs and efficiently serve you. Your satisfaction is our best reward. We are looking forward to your visit for joint growth for Stainless steel pipe welding Factory – carbon steel rectangular tube – Future Metal , The product will supply to all over the world, such as: Manila, Ecuador, Chile, Our products are mainly exported to Europe, Africa, America, the Middle East and Southeast Asia and other countries and regions. We have enjoyed a great reputation among our customers for quality products and good services.We would make friends with businessmen from at home and abroad, following the purpose of "Quality First, Reputation First, the Best Services."

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.