China High quality Cylinder polishing tube Manufacturer – Cylinder Tube DNC Pneumatic Cylinder Aluminum Tube – Future Metal

China High quality Cylinder polishing tube Manufacturer – Cylinder Tube DNC Pneumatic Cylinder Aluminum Tube – Future Metal Detail:

The main purpose of hydraulic cylinder

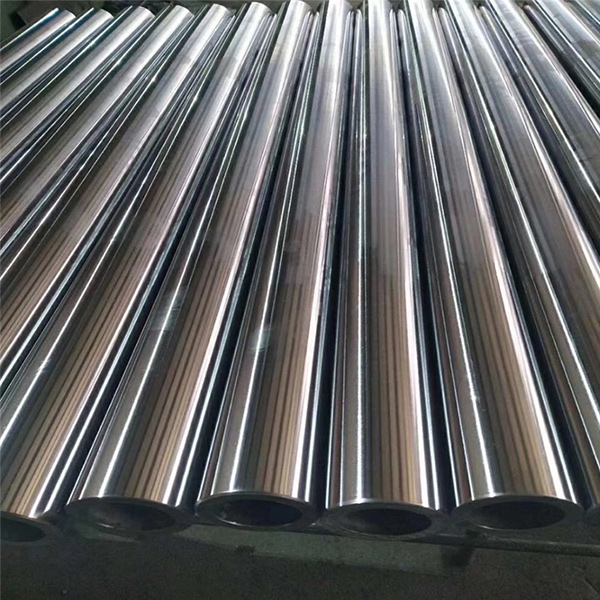

Hydraulic and pneumatic cylinders; hydraulic pipelines; pipes for spinning, textile and printing machinery;

Automobile shock absorber pipe; shaft sleeve; piston rod and precision alloy steel pipe.

According to customer requirements, we can also provide: fixed-length tubes, honing tubes, and special heat-treated tubes.

In order to obtain a good honing effect, in addition to the selection of good honing tools and the correct selection of grinding rod materials and particle size, the use of process parameters during honing also has a large impact on processing quality and productivity. Hydraulic cylinder refers to the pressure exerted by the sand bar on the surface of the workpiece, which is determined by the hardness of the processed surface, the nature of the grinding bar and the requirements of the processed surface roughness.

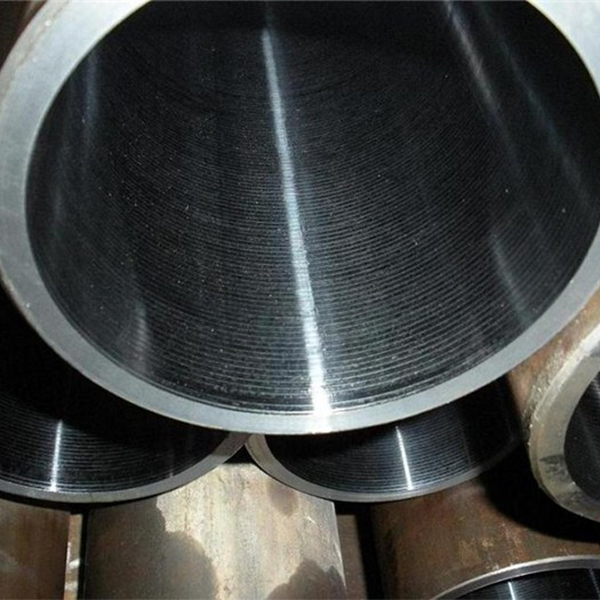

Cylinders are the main components of hydraulic cylinders, single pillars for mines, hydraulic supports, gun barrels and other products. The quality of their processing directly affects the life and reliability of the entire product. The cylinder barrel has high processing requirements, and its inner surface roughness is required to be Ra0.4~0.8&um, and the requirements for coaxiality and wear resistance are strict.

The use of rolling processing, because the surface layer leaves the surface residual compressive stress, it helps to close the surface micro-cracks and hinder the expansion of erosion. So as to improve the surface corrosion resistance, and can delay the generation or expansion of fatigue cracks, thereby improving the fatigue strength of the cylinder. Through roll forming, a cold work hardened layer is formed on the rolled surface, which reduces the elastic and plastic deformation of the contact surface of the grinding pair, thereby improving the wear resistance of the inner wall of the cylinder and avoiding burns caused by grinding. After rolling, the surface roughness value is reduced, which can improve the matching performance.

Product Display

Product detail pictures:

Related Product Guide:

We persist with the principle of "quality 1st, assistance initially, continual improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for China High quality Cylinder polishing tube Manufacturer – Cylinder Tube DNC Pneumatic Cylinder Aluminum Tube – Future Metal , The product will supply to all over the world, such as: Slovakia, Miami, Mauritania, Our items are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our merchandise and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!