Famous Stainless steel pipe welding Products – LSAW Carbon SteelPipe Welded Steel Pipe – Future Metal

Famous Stainless steel pipe welding Products – LSAW Carbon SteelPipe Welded Steel Pipe – Future Metal Detail:

Description of the main production process of large-diameter straight seam welded pipe:

1. Plate inspection: After the steel plate used to manufacture the large-diameter submerged arc welded straight seam steel pipe enters the production line, the full plate ultrasonic inspection is first carried out;

2. Edge milling: double-sided milling of the two edges of the steel plate by a milling machine to achieve the required plate width, plate edge parallelism and bevel shape;

3. Pre-bending: Use a pre-bending machine to pre-bend the edge of the board so that the edge of the board has a curvature that meets the requirements;

4. Forming: On the JCO forming machine, first half of the pre-bent steel plate is pressed into a “J” shape through multiple stepping steps, and then the other half of the steel plate is also bent and pressed into a “C” shape, and finally an opening is formed “O” shape

5. Pre-welding: Join the formed longitudinally welded steel pipes and use gas shielded welding (MAG) for continuous welding;

6. Internal welding: use longitudinal multi-wire submerged arc welding (up to four wires) to weld on the inner side of the straight seam steel pipe;

7. External welding: use longitudinal multi-wire submerged arc welding to weld on the outside of the longitudinal submerged arc welded steel pipe;

8. Ultrasonic inspection I: 100% inspection of the inner and outer welds of the longitudinally welded steel pipe and the base materials on both sides of the weld;

9. X-ray inspection I: 100% X-ray industrial television inspection of the inner and outer welds, using an image processing system to ensure the sensitivity of flaw detection;

10. Diameter expansion: expand the total length of the submerged arc welded straight seam steel pipe to improve the dimensional accuracy of the steel pipe and improve the distribution of the internal stress of the steel pipe;

11. Hydraulic test: The expanded steel pipes are inspected one by one on the hydraulic testing machine to ensure that the steel pipe meets the test pressure required by the standard. The machine has automatic recording and storage functions;

12. Chamfering: Process the pipe end of the qualified steel pipe to meet the required pipe end groove size;

13. Ultrasonic inspection Ⅱ: Perform ultrasonic inspection again one by one to check the possible defects of the longitudinally welded steel pipe after the diameter expansion and water pressure;

14. X-ray inspection Ⅱ: X-ray industrial television inspection and filming of pipe end welds on the steel pipe after the expansion and hydraulic test;

15. Tube end magnetic particle inspection: carry out this inspection to find tube end defects;

16. Anti-corrosion and coating: Qualified steel pipes are anti-corrosion and coating according to user requirements.

UOE LSAW Pipes

| Outside Diameter | Φ508mm- 1118mm (20″- 44″) |

| Wall Thickness | 6.0-25.4mm 1/4″-1″ |

| Length | 9-12.3m (30′- 40′) |

| Quality Standards | API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA |

| Grades | API 5L A-X90,GB/T9711 L190-L625 |

JCOE LSAW Pipes

| Outside Diameter | Φ406mm- 1626mm (16″ – 64″ ) |

| Wall Thickness | 6.0- 75mm (1/4″ – 3″ ) |

| Length | 3-12.5m ( 10′- 41′ ) |

| Quality Standards | API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA |

| Grades | API 5L A-X100, GB/T9711 L190-L690 |

Tolerance of Outside Diameter and Wall Thickness

|

Types |

Standard |

|||||

|

SY/T5040-2000 |

SY/T5037-2000 |

SY/T9711.1-1977 |

ASTM A252 |

AWWA C200-97 |

API 5L PSL1 |

|

|

OD deviation |

±0.5%D |

±0.5%D |

-0.79mm~+2.38mm |

<±0.1%T |

<±0.1%T |

±1.6mm |

|

Wall thickness |

±10.0%T |

D<508mm, ±12.5%T |

-8%T~+19.5%T |

<-12.5%T |

-8%T~+19.5%T |

5.0mm |

|

D>508mm, ±10.0%T |

T≥15.0mm, ±1.5mm |

|||||

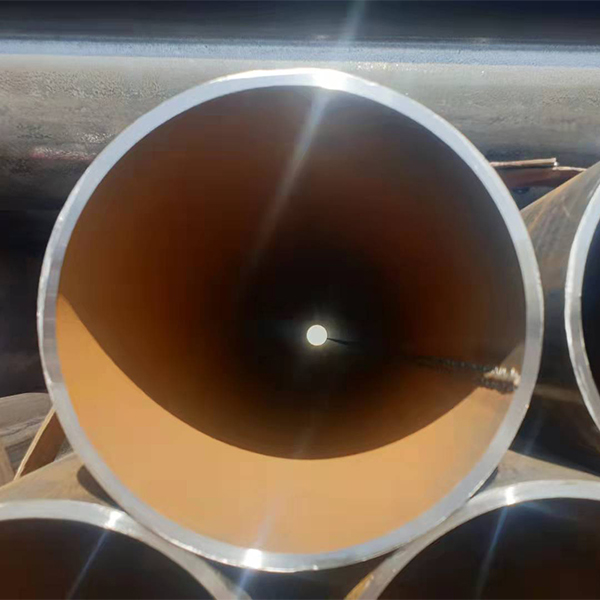

Product Display

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is definitely the persistent conception of our corporation to the long-term to establish alongside one another with customers for mutual reciprocity and mutual profit for Famous Stainless steel pipe welding Products – LSAW Carbon SteelPipe Welded Steel Pipe – Future Metal , The product will supply to all over the world, such as: Swaziland, Atlanta, Rwanda, Our company insists on the purpose of "takes service priority for standard, quality guarantee for the brand, do business in good faith, to provide professional, rapid, accurate and timely service for you". We welcome old and new customers to negotiate with us. We will serve you with all sincerity!

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!